Technical Specs

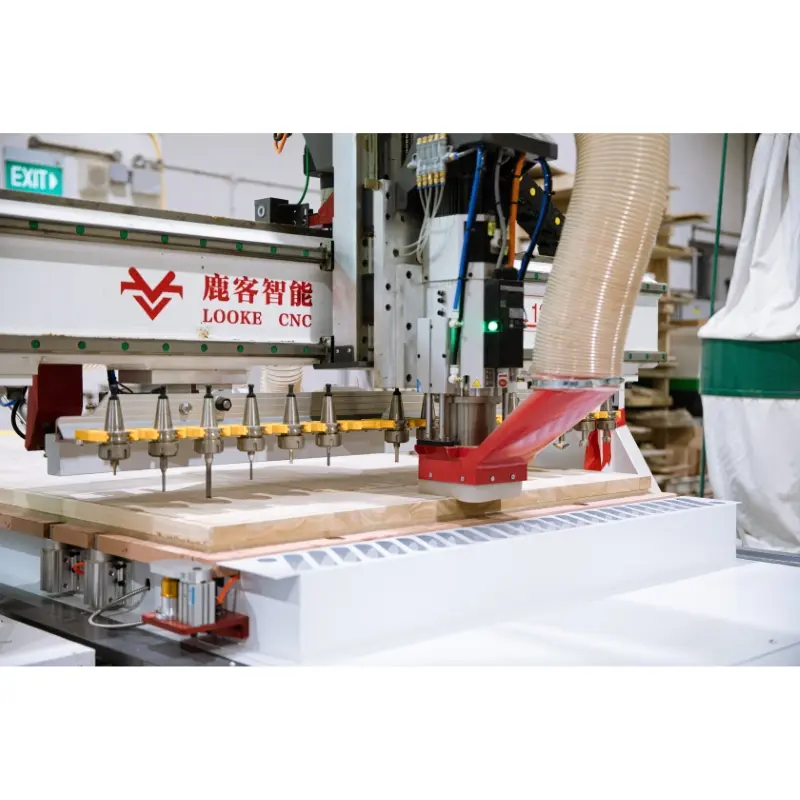

| Model | LOOKE-L12 |

| Machine Size | 2200*2600 mm |

| Work Envelope (XYZ) | 1220*2750*200 mm |

| Bridge Clearance | 70 mm |

| Repositioning Resolution | ±0.05 mm |

| Resolution | ±0.05 mm |

| Power of Spindle | 9.0KW |

| Spindle Motor | Air-cooled spindle, Changsheng, Changzhou |

| Spindle Speed | 6000 - 24000 rpm |

| Max Speed | 110,000 mm/min |

| Max Cutting Speed | 25,000 mm/min |

| Working Voltage | AC380V/5PH/50HZ |

| Command Code | G code |

| Software Control System | New generation FC system |

| Software | Intelligent design and layout production software |

| Drive System | Taiwan's Han's Yu servo drive of 1.5KW |

| Inverter | Shenzhen EST 11KW inverter |

| Guide Rail | Imported Optional 25/30mm Guide Rail |

| Drive Type | Precision helical racks for X and Y axes, ball screw for the Z axis |

| Reducer | Zhongda Lide reducer |

| Bed Structure | Welded with thick-walled square steel |

| Tabletop | Vacuum adsorption (stainless steel water tank) |

| Maximum Tool Holding Handle Diameter | ⌀12.7 mm |

| Tool Magazine Capacity | Inline pneumatic tool magazine, 8-16 tool switching (optional) |

| Accessories - Vacuum Pump | 7.5KW water pump, matched with the equipment |

| Accessories - Dust Collector | Matched with the equipment, automatically removes processing waste |

| Accessories - Tool Kit | Toolholder φ6 mm, φ12.7 mm, wrench, etc. |

| Full Sheet | Hidden tool setting gauge, one-key full sheet |

| Automatic Positioning | Standard automatic positioning function |

| Automatic Feeding | After processing is complete, it can automatically feed materials |

Frequently Asked Questions

CNC machines can work with a wide range of materials, including metals (aluminum, steel), plastics, wood, and composites.

Precision, repeatability, efficiency, and the ability to create complex shapes are some advantages of using CNC machines. They also reduce the need for manual labor.

Yes, CNC machining is well-suited for high-volume production. Its automation and repeatability make it efficient for large-scale manufacturing.

CNC machines are programmed using G-code, a language that provides instructions for tool movements, speeds, and other parameters. CAM (Computer-Aided Manufacturing) software is often used for programming.

Safety measures include wearing appropriate personal protective equipment, ensuring proper machine enclosure, and following operating guidelines. Proper training for operators is crucial.