Compact Size. Industrial Performance.

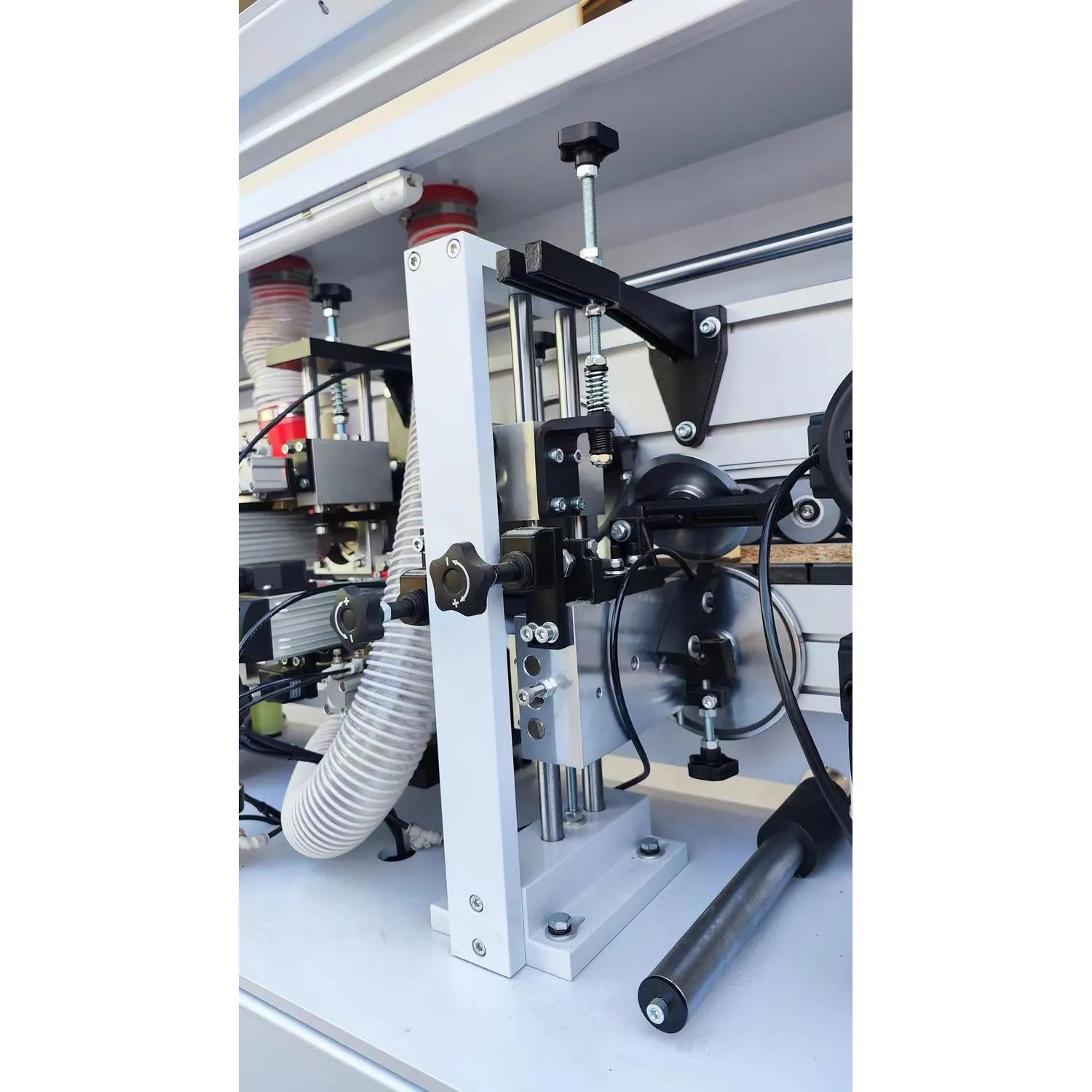

The SICAR ECO F Series edge bander packs industrial-grade precision into a compact, workshop-friendly footprint. It’s not just another small machine—it’s built with the same core modules found in large-scale systems, ensuring stable, high-accuracy performance from start to finish.

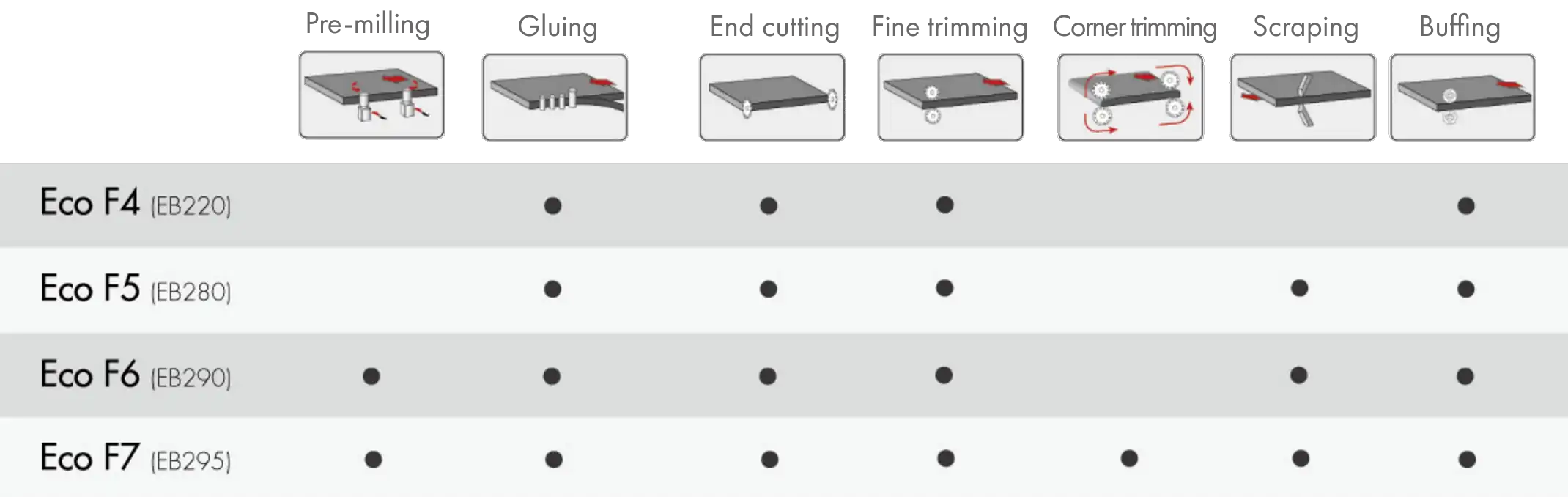

Complete Edge Processing.

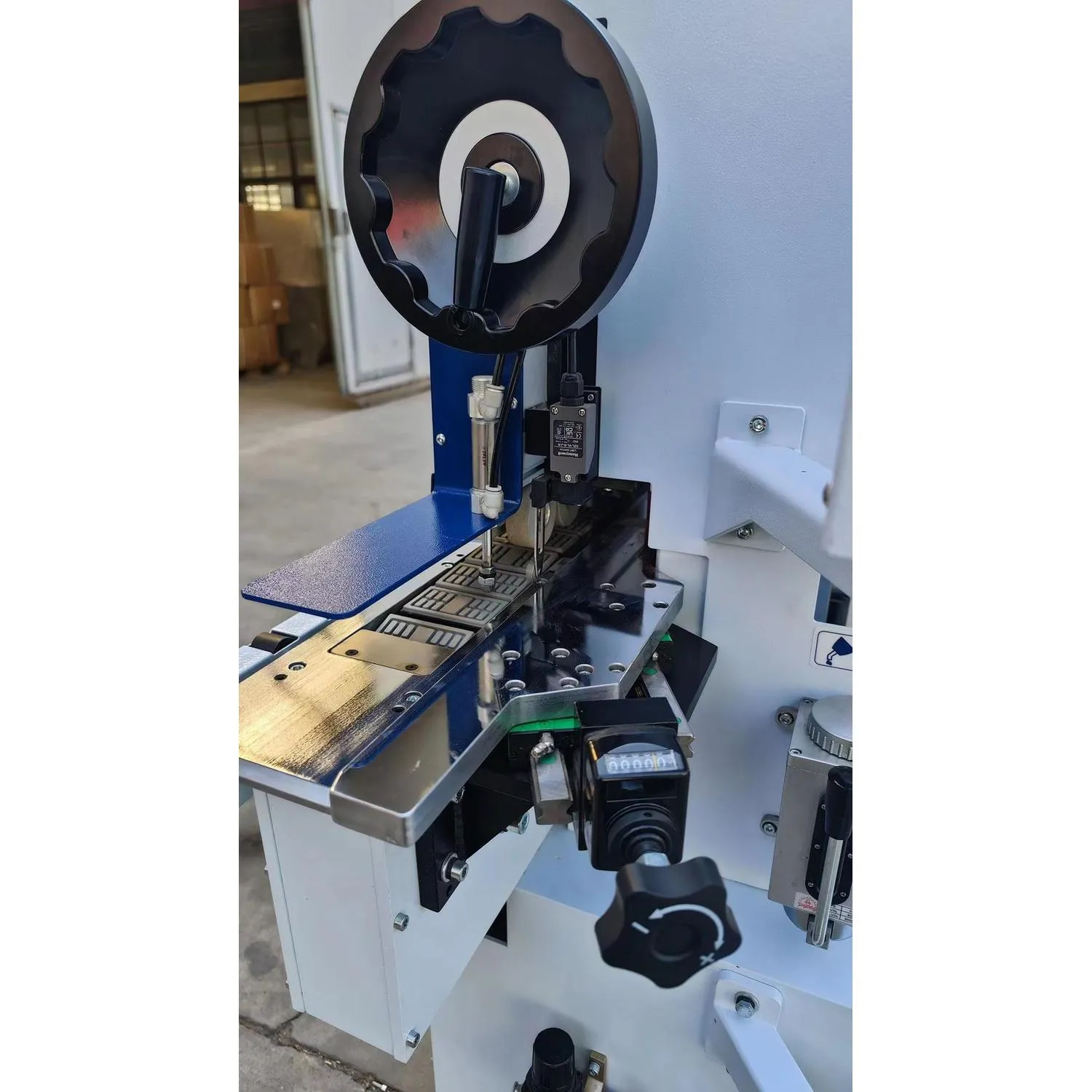

Gluing, end cutting, fine trimming, buffing—all standard. Some models also include pre-milling, corner trimming, and scraping, making it perfect for achieving professional finishes even on complex edges and materials.

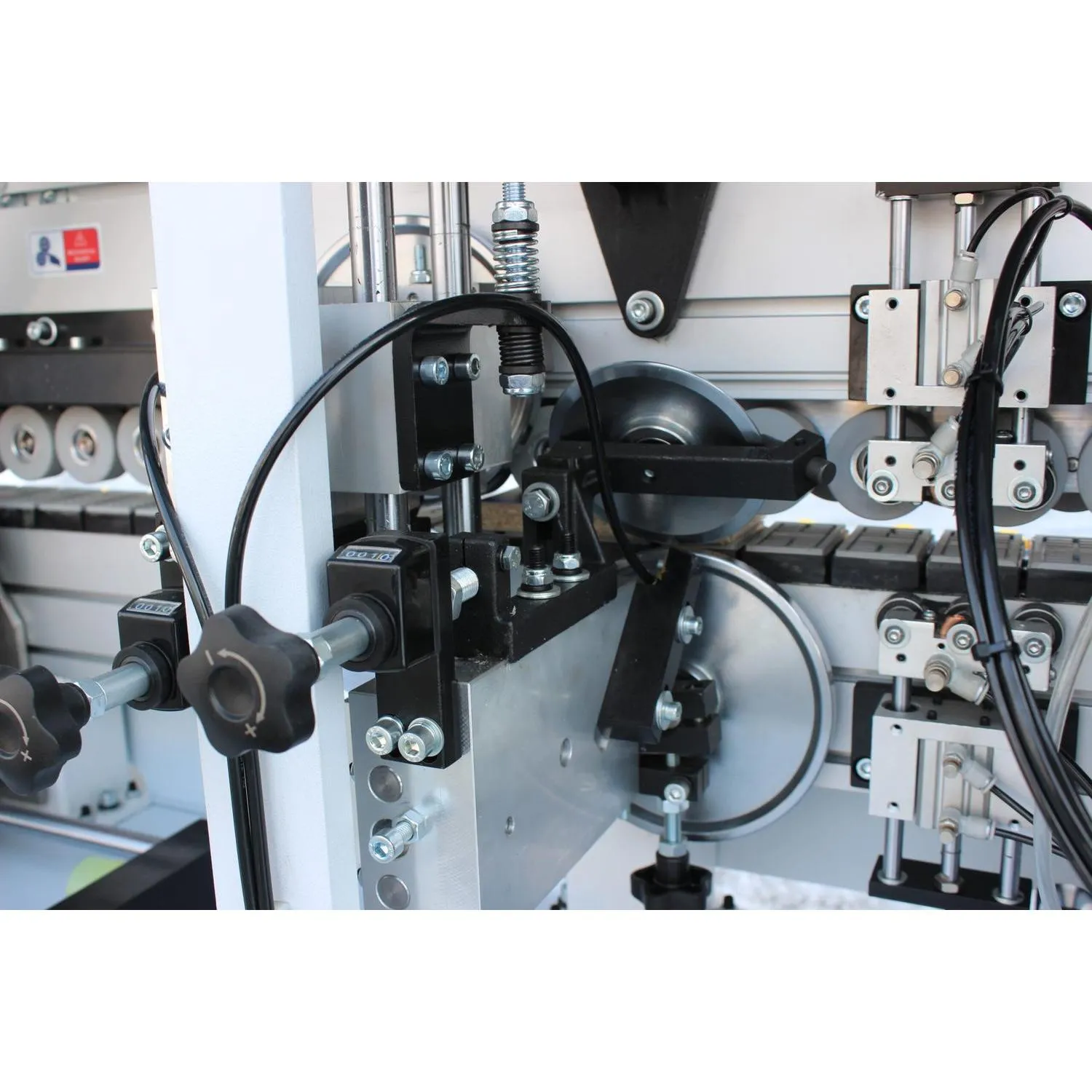

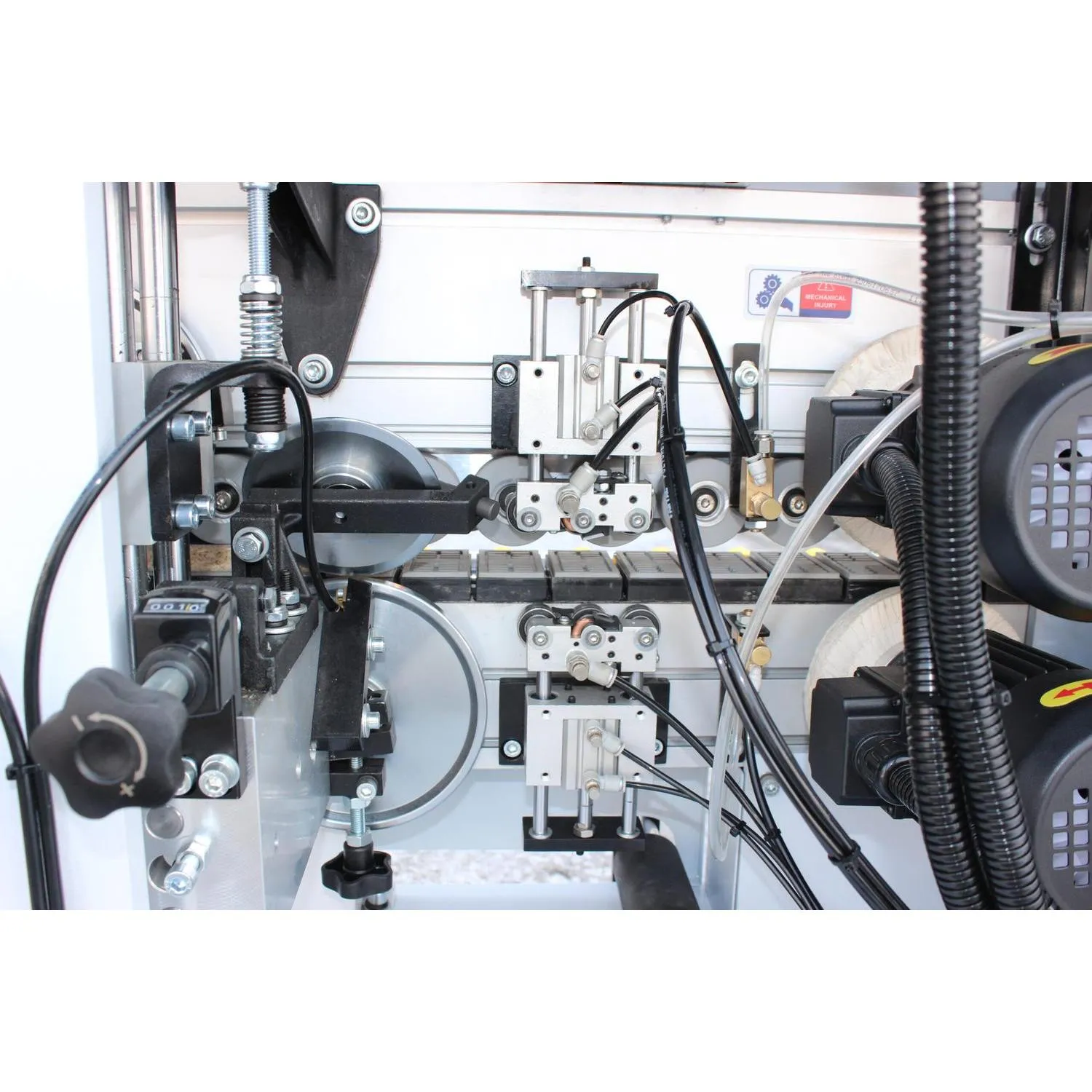

Smart Engineering for Flawless Results.

Pre-milling with diamond cutters for clean, straight board edges.

Even glue application ensures strong, lasting adhesion.

Fine trimming & corner triming deliver smooth, refined edges with precision.

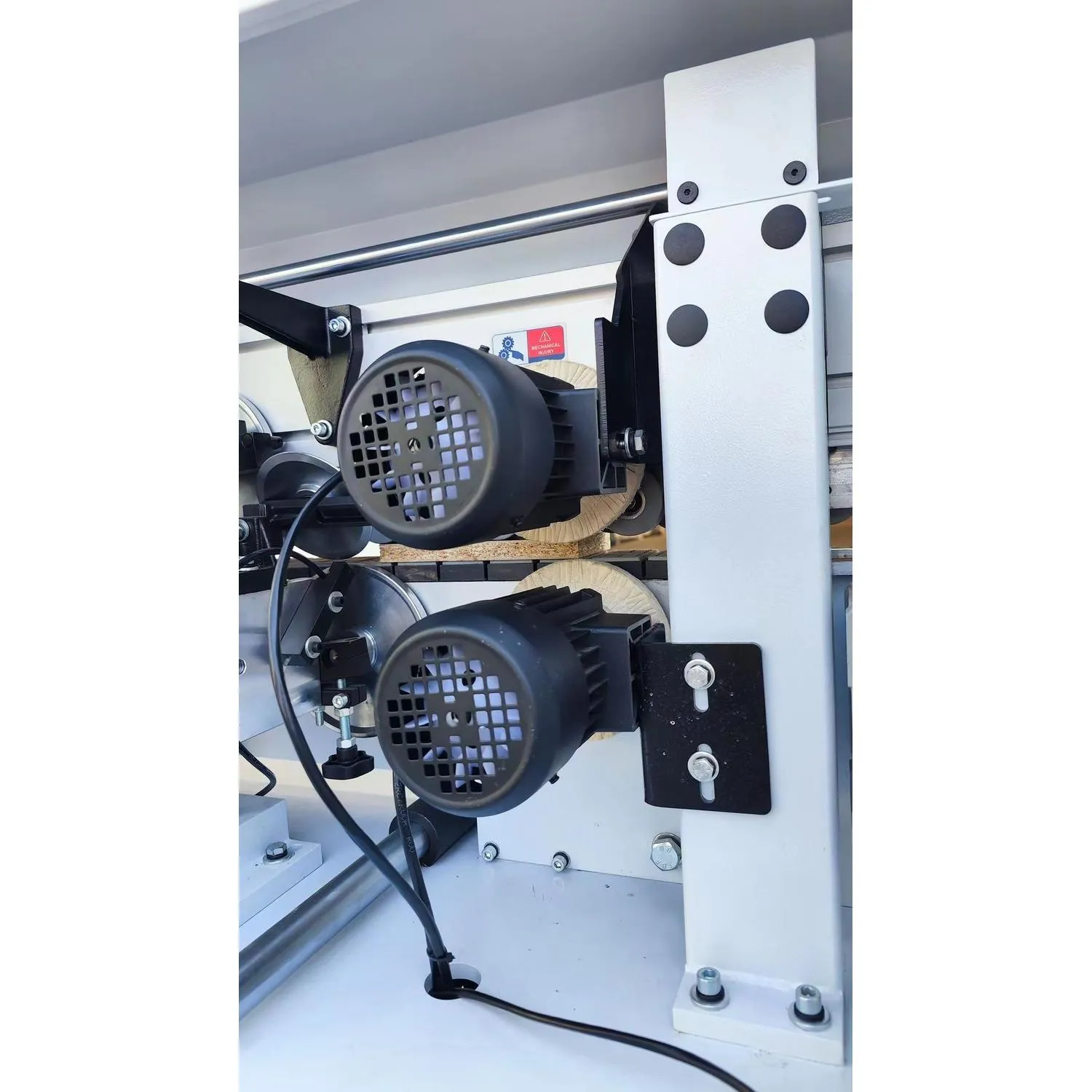

Scraping & buffing clean up glue lines and polish the finish.

Built to Last.

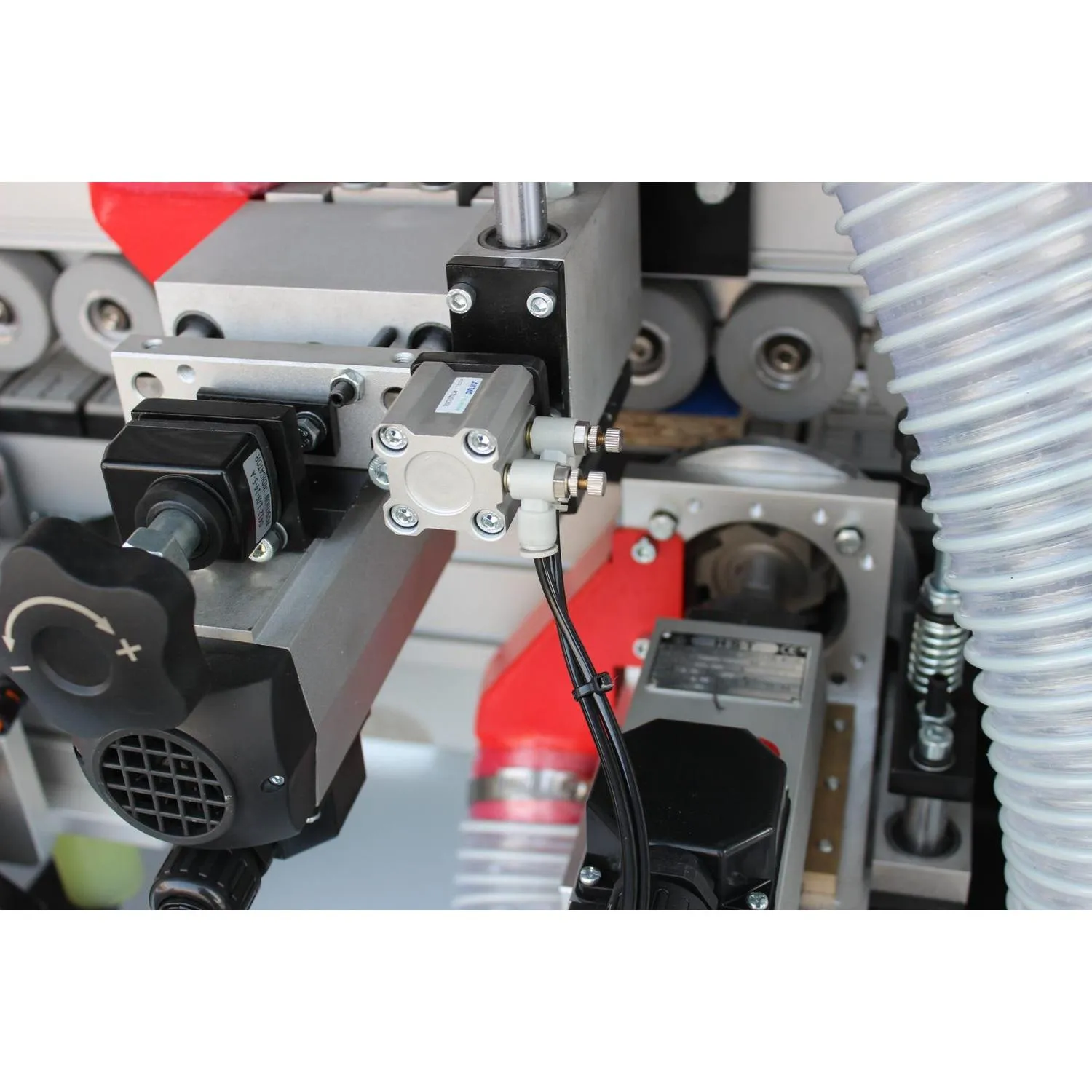

Inside, it’s powered by premium parts: Siemens electronics, Delta components, and Honeywell safety systems. With protections like phase loss guards and pressure control, it’s built for long-term reliability.

Technical Specifications

| Tape Thickness | 0.4–3 mm |

| Tape Height | 12–45 mm |

| Workpiece Thickness | 10–45 mm |

| Feeding Speed | 11 m/min |

| Air Pressure | 0.6–0.8 MPa |

| Total Power | 6.5 kW |

| Machine Outline Size | 3150x700x1300 mm |

| Packing Size | 2900x650x1280 mm |

| Weight | 800 Kg |

| Control System | Delta |

| Electrical Equipment | Delta |

| Safety Device | Honeywell |

| Low-voltage Components | Siemens |