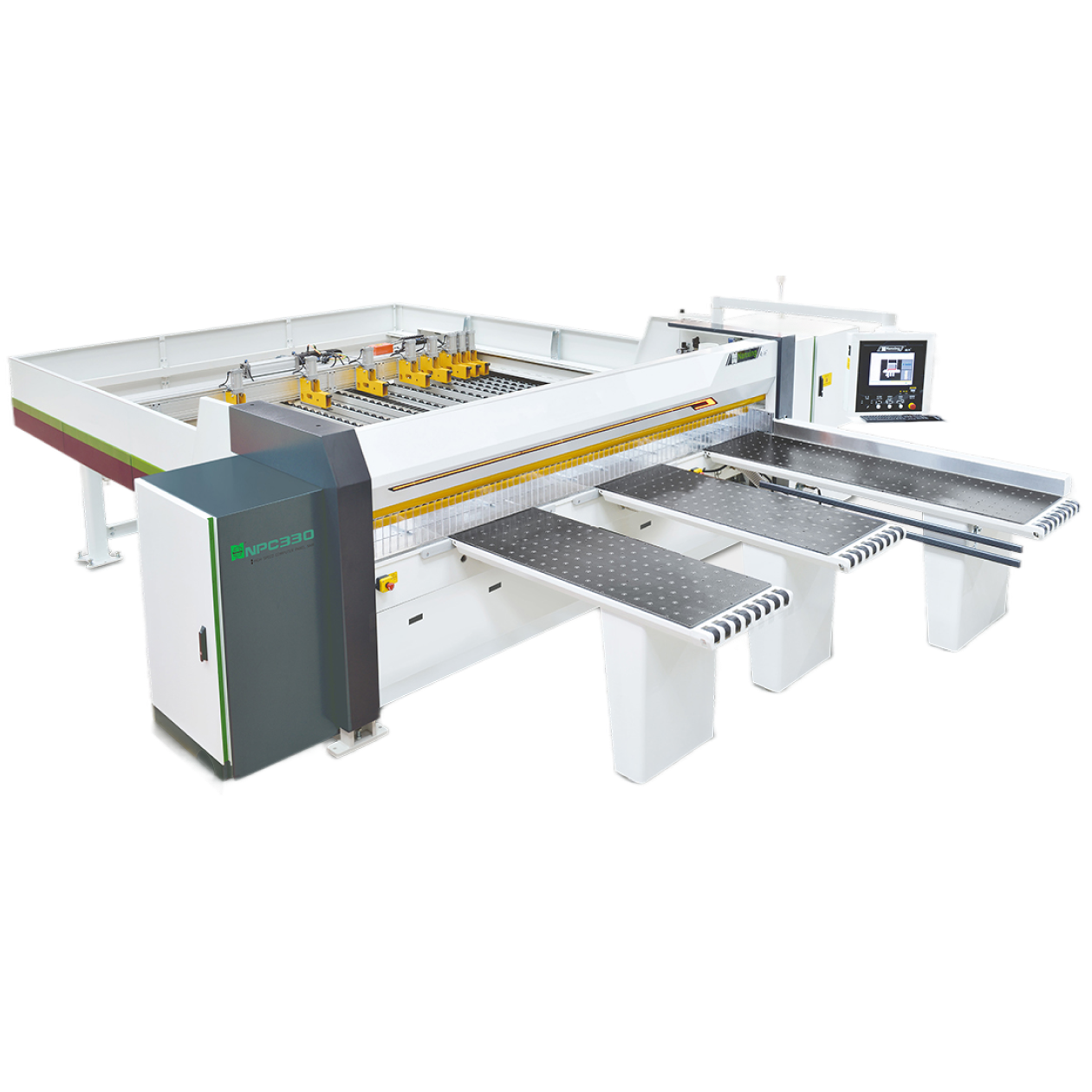

Technical Specifications

| Model | NPC330 |

| Equipment Size | 6900 × 5400 × 1820 mm |

| Net Weight | 5300 kg |

| Total Power | 23.5 kw |

| Maximum Cutting Length | 3300 mm |

| Maximum Cutting Thickness | 90 mm |

| Max Forward Speed of Saw Carriage | 90 m/min |

| Max Backward Speed of Saw Carriage | 120 m/min |

| Max Automatic Feeding Speed | 85 m/min |

| Main Saw Motor | 15 kw |

| Main Saw Speed | 3910 rpm |

| Slot Saw Motor | 2.2 kw |

| Slot Saw Speed | 4300 rpm |

| Dust Extraction Port | ⌀150mm x 3 |

| Fan Power | 2.2 kw |

| Pneumatic Floating Table | Large, low-friction tabletop with pneumatic floating balls, facilitating smooth material movement without scratching |

| Quick Start Cutting Device | Continuous saw pull rods added to the air-floating table, operation in line with ergonomic design, making it convenient and quick to start cutting. |

| Pressure Beam | Single pressure beam for uniform pressure on the entire surface of the board |

| Pressure Beam Guard | Pressure beam guard for safety. |

| Steel Tabletop | Steel tabletop above the saw carriage, sturdy and wear-resistant, improving processing accuracy. |

| Clamping System | Sturdy H shaped steel as precise guiding supports on both sides. Number of clamps: 8. CNC processed clamps, single-clamp structure, vertical gripping mechanism. |

| Saw Carriage and Drive | Driven by servo motor, gear, and rack transmission. Independent power control for main and slot saws. Automatic height adjustment for the main saw based on board height. Electric adjustment for the rise and fall of the slot saw, both front and rear. |

| Cutting Side Guide Device | Side alignment device on the saw carriage, effectively saving alignment time for narrow and long board processing. |

| Anti-drop Device | Device on the saw carriage preventing small materials from falling, ensuring stable operation of the saw carriage. |

| Feeding Mechanism | Uses high-quality reducer to ensure cutting precision and stability. |

| Intelligent Lubrication System | Machine equipped with an automatic lubrication system, automatically lubricating all moving parts, ensuring precision and extending the service life of the equipment. |

| Electrical Components | Electrical components are all from well-known brands. |

| Industrial Computer Control | Equipped with a color display, USB interface, network card, mouse, and keyboard. Industrial computer control, Windows 7 operating system, and specialized cutting software from Nanxing. |

| Equipment Monitoring | Real-time monitoring of equipment usage, clear display of diagnostic systems to immediately identify the root cause of errors, improving efficiency in cutting board materials. |

| Standalone Professional Cutting Optimization Software | Nanxing optimization software with features such as optimization, layout, residue list, texture selection, etc. |

| Tool Specifications | Main Saw: Outer diameter ⌀380, Shaft diameter ⌀60. Sub Saw: Outer diameter ⌀200, Shaft diameter ⌀45 |

Frequently Asked Questions

The saw is designed to efficiently cut a variety of sheet materials, including wood, MDF, particleboard, and more.

The automatic adjustment feature, particularly in beam height, tailors itself to the thickness of the board being processed. This reduces unnecessary idle movements, enhancing cutting efficiency.

Yes, the equipment includes features such as the cutting side guide device and clamping system designed to handle narrow and long boards with precision.

Both the main and sub-saws feature a quick-detach mechanism, allowing for fast and convenient blade replacement.

Absolutely. The equipment seamlessly integrates with design and order processing software, enabling smart and customized furniture production.

The saw is equipped with an anti-drop device to prevent smaller materials from falling into the saw seat, ensuring stable operation.