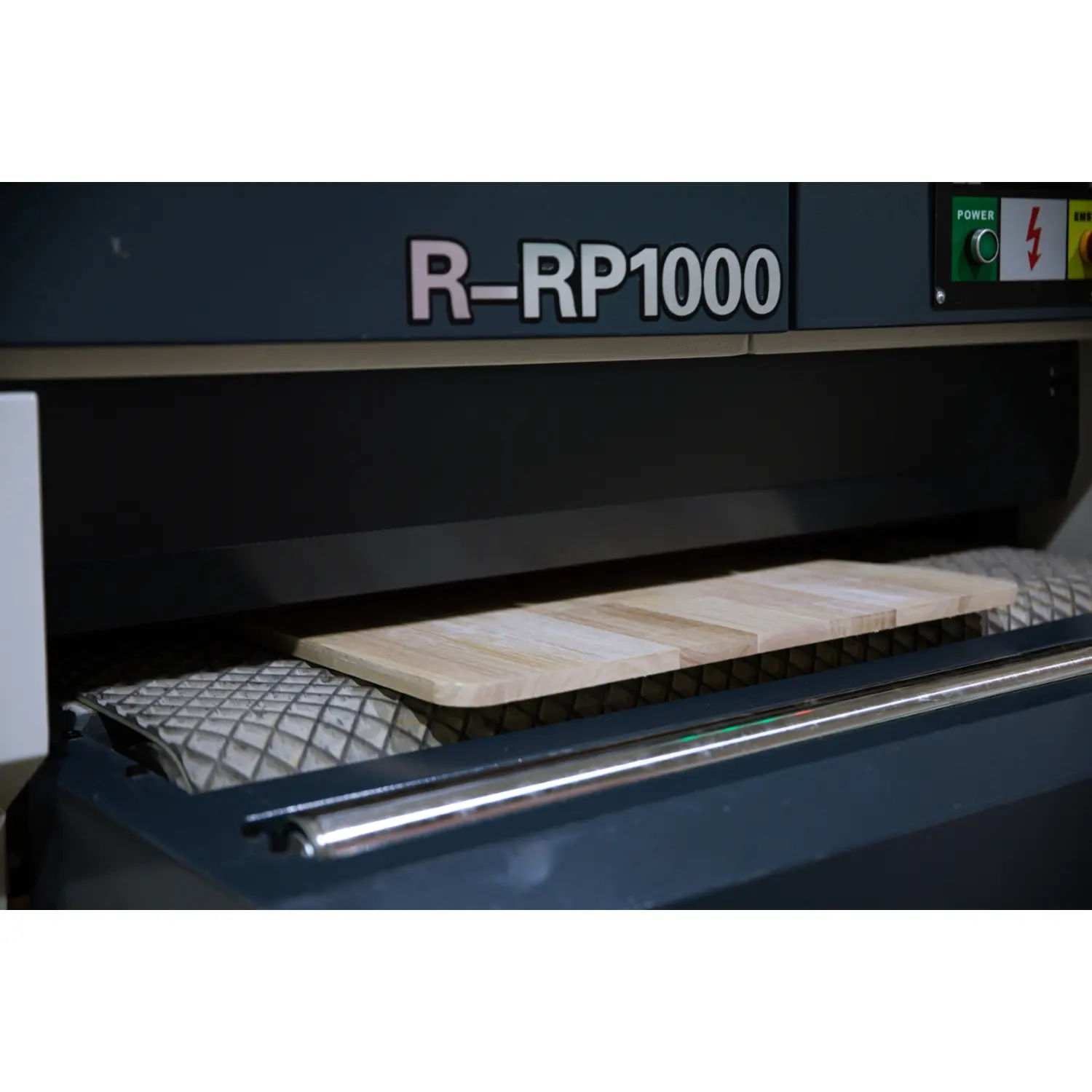

Technical Specifications

| First Sanding Motor | 15 kW (4-pole pure copper core national standard motor) |

| Second Sanding Motor | 11 kW (4-pole motor with pure copper core national standard) |

| Heavy-duty LG Rubber Drum | 190mm Diameter x 2 |

| Conveyor Belt Motor | 1.5 kW (stepless speed regulation, pure copper core national standard) |

| Platform Lift Motor | 370 kW (national standard motor with pure copper core) |

| Total Power | 28.55 kW |

| Maximum Processing Board Width | 1000mm |

| Maximum Processing Board Thickness | 3-120mm |

| Maximum Processing Board Length | >340mm |

| Working Pressure | 0.6-0.8 MPa |

| Sanding Belt Speed | 20 m/min |

| Conveyor Speed | 6-14 m/min |

| Sandbag Size | 1020 - 2000mm |

| Machine Weight | 2.0 tons |

| Body | National standard steel welded gantry milling |

| Bearings | FSB brand high-speed bearings |

| Photoelectric | South Korean Autonics imported photoelectric |

| Conveyor Belt | Seven-layer laminated Best conveyor |

| Conveyor Platform | Solid 9 cm thick marble |

| Conveyor Belt Motor | Qingdao Yibang |

| Main Motor | Jubang, Heavy-duty Motor |

| Electrical | Zhengtai |

| Solenoid Valve | Yadeke |

| Sheet Metal | Laser cutting and spray treatment |

Frequently Asked Questions

It is versatile and can handle a wide range of materials, including wood, metal, plastic, and composites.

Heavy-duty sanding machines are characterized by their robust construction, powerful motors, and the ability to handle larger workpieces with greater efficiency.

Consider factors such as motor power, sanding belt speed, table size, and the overall build quality for heavy-duty applications.

Yes, these machines are designed to accommodate a range of abrasive grits, making them suitable for both rough material removal and fine finishing.

Yes, these machines are versatile and can be adapted for various project sizes, making them suitable for both small workshops and large-scale industrial operations.

Yes, many heavy-duty models are designed for continuous use in industrial settings, ensuring durability and reliability during extended operation.