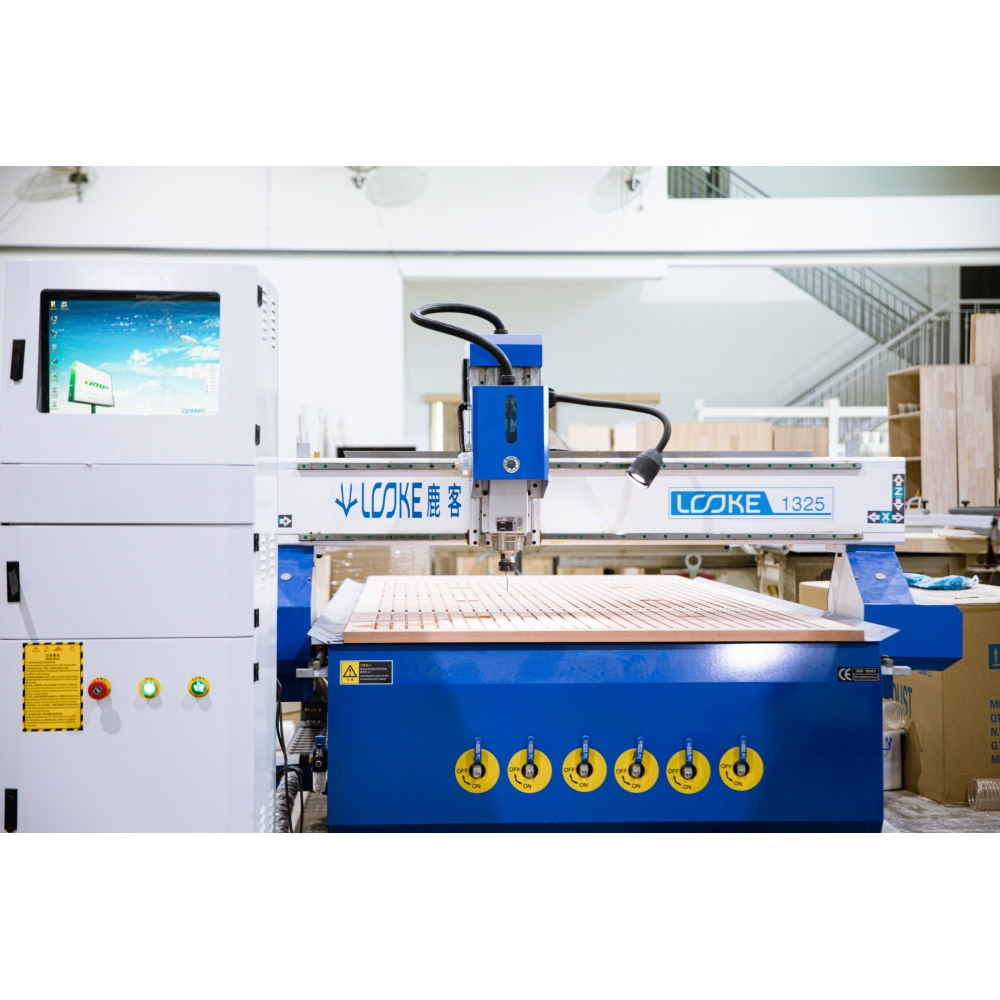

Technical Specifications

| Model | LOOKE-1325 |

| Machine Size | 1380*2800MM |

| Work Envelope (XYZ) | 1300*2500*200mm |

| Bridge Clearance | 200mm |

| Repositioning Resolution | ±0.02mm |

| Resolution | ±0.025mm |

| Power of Spindle | 3.2 KW |

| Spindle Motor | Jiangsu, Changsheng 3.2KW (Brand and Power Rating) |

| Water Cooling | Yes |

| Spindle Speed | 6000-18000 rpm |

| Max Speed | 80m/Min |

| X Axis | 60m/min |

| Y Axis | 110m/min |

| Z Axis | 10m/min |

| Max Cutting Speed | 25m/Min |

| Working Voltage | 380V/220V 50Hz |

| Command Code | HPGL G-code |

| Software Control System | NC STUDIO |

| Drive System | Motor Drive |

| Leadshine Stepper Motor | Leadshine Drive |

| Inverter | Shenzhen EST (Zero-Second Switching) 3.7KW * 1 Unit (Four-in-One Inverter) |

| Guide Rail | Imported 20mm Guide Rail |

| Drive Type - Rack | LOOKE Dedicated Rack 2.0 |

| Drive Type - Ball Screw | Ball Screw |

| Wiring | High-Flex Cable |

| Bed Structure | Welded Steel Pipe Bed Frame |

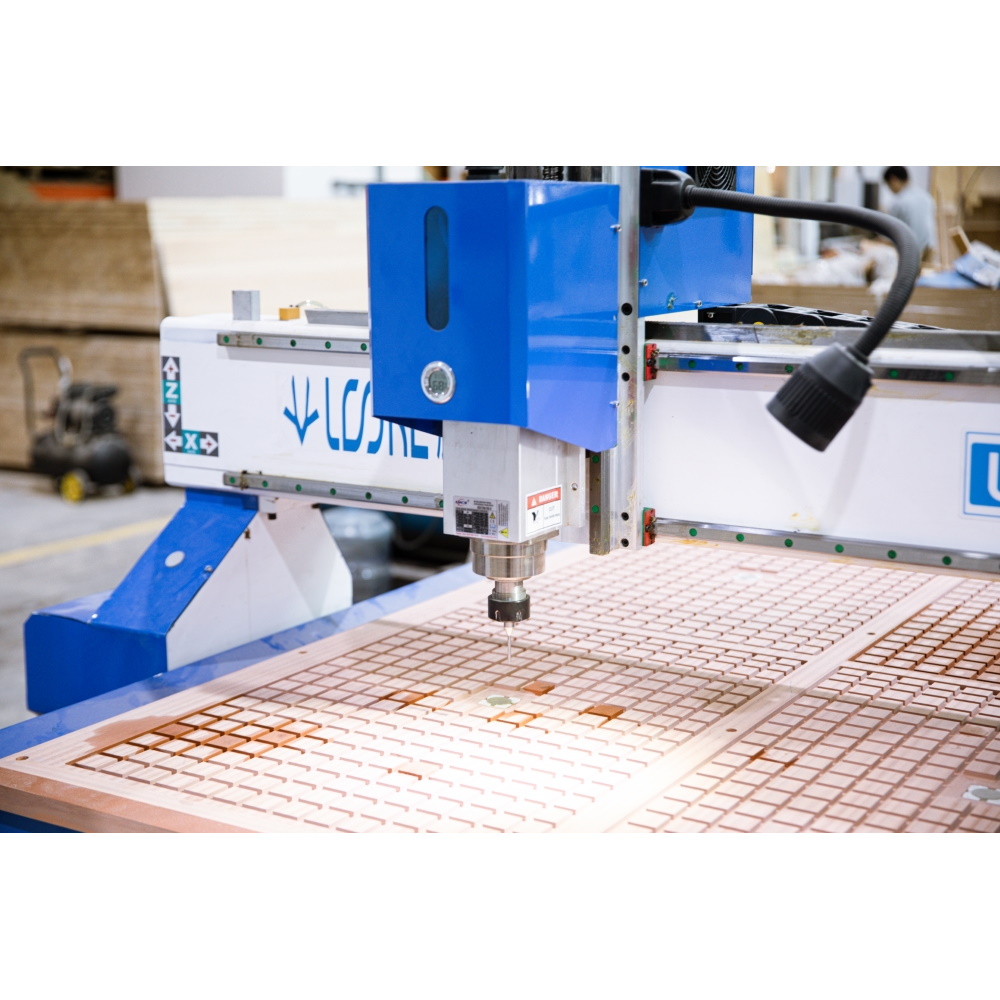

| Tabletop | Intelligent Material + PVC Tabletop |

| Total Power (Approximate) | 12kw |

Frequently Asked Questions

CNC machines can work with a wide range of materials, including metals (aluminum, steel), plastics, wood, and composites.

Precision, repeatability, efficiency, and the ability to create complex shapes are some advantages of using CNC machines. They also reduce the need for manual labor.

Yes, CNC machining is well-suited for high-volume production. Its automation and repeatability make it efficient for large-scale manufacturing.

CNC machines are programmed using G-code, a language that provides instructions for tool movements, speeds, and other parameters. CAM (Computer-Aided Manufacturing) software is often used for programming.

Safety measures include wearing appropriate personal protective equipment, ensuring proper machine enclosure, and following operating guidelines. Proper training for operators is crucial.